Recently, professor Zhen Zhao, professor Xuehua Yu and master student Chunlei Zhang of Shenyang Normal University published an online review article entitled Research progress on preparation of 3DOM based oxide catalysts and their catalytic performances for the collaboration of diesel soot particles in the well-known academic journal Applied Catalyst B: Environmental (impact factor: 24.319) in the chemical field.

Diesel engines have been widely used in many heavy industries such as agriculture, construction, and transportation due to their high thermal efficiency, high power, long life, and good power performance. However, the environmental pollution caused by diesel engine exhaust emissions is also becoming increasingly severe. Among these, soot particles are not only a main cause of hazy weather but also adsorb carcinogenic substances such as volatile organic compounds and polycyclic aromatic hydrocarbons. Soot particles with carcinogens can cause serious health problems such as asthma, lung cancer, and other cardiovascular diseases. At present, as the most effective way to eliminate diesel engine soot particle emissions, the development of high-performance soot combustion catalysts has become a key factor in the post-treatment purification technology. The catalytic combustion of soot particles is a kind of gas-solid (soot particles)-solid (catalyst) multiphase catalytic deep oxidation reaction.

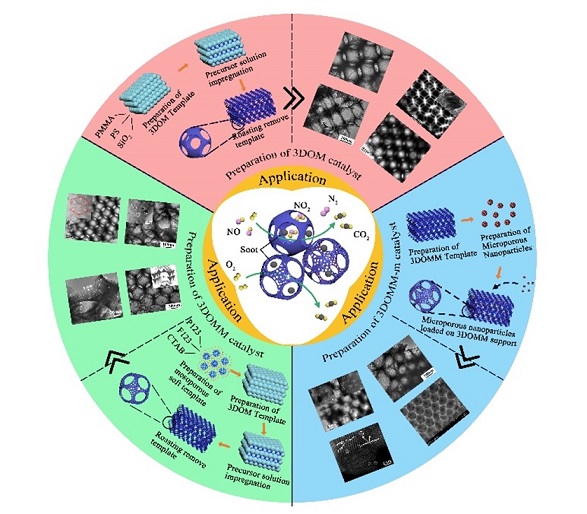

Therefore, the catalytic performance of catalysts for soot combustion mainly depends on their intrinsic activity and the contact efficiency between soot particles and the catalyst active sites. In recent years, researchers have designed and prepared various highly intrinsic active soot combustion catalysts by adjusting the catalyst composition, and developed a large number of special morphologies to significantly enhance the contact efficiency between the catalysts and soot particles. Three-dimensional ordered which further improves catalytic activity. To further improve 3DOM catalysts, researchers have constructed mesoporous and microporous structures on the basis of a three-dimensional ordered macroporous skeleton structure; this could further improve the specific surface area of the catalyst while also promoting the adsorption and activation of small molecular substances such as O2 and NOx under the premise of ensuring unrestricted flow through the internal pores of the catalyst.

In this paper, the preparations of three-dimensional ordered macroporous catalysts, three-dimensional ordered micro/meso-macroporous catalysts, and three-dimensional ordered micro-meso-macroporous catalysts are introduced. The latest research progress on the catalytic performance and mechanism for the combustion of soot particles over 3DOM catalysts is summarized. Finally, the problems and future development trends of three-dimensional ordered macroporous catalysts for soot combustion are proposed.

Shenyang Normal University is the first completion unit and communication unit of the work, Chunlei Zhang, a postgraduate student of the College of Chemistry and Chemical Engineering, is the first author of the paper, and professor Zhen Zhao and professor Xuehua Yu are the corresponding authors of the paper. This research was funded by National Natural Science Foundation of China (22072095, U1908204); Key Research and Development Program of MOST (2017YFE0131200) for collaboration between China and Poland; University Joint Education Project for China-Central and Eastern European Countries (2021097); National Engineering Laboratory for Mobile Source Emission Control Technology (NELMS2018A04); Key Project of Graduate Education and Teaching Reform of Shenyang Normal University (YJSJG220210022); University level innovation team of Shenyang Normal University; Major Incubation Program of Shenyang Normal University (ZD201901).

Original link: https://doi.org/10.1016/j.apcatb.2022.121946